FastCUT® cutting software produces optimized cutting plans for rectangular, linear & cut to length stock such as plate, wood/plywood panels and flat glass. Powerful nesting algorithms deliver substantial savings in seconds and the program also generates pick lists. Use for metal, wood, glass, marble, plastics and 'like' products for maximize yield. Handles multiple stock sizes and parts consolidation. Optimize on material or handling. Covers sheared and sawn processing with kerf width allowance for saw blade.

Optimization uses the guillotine cutting method when all cuts are done from one side of a panel completely to another side. Some cutting machines require simple cutting operation with only one sheet rotation; other machines are more sophisticated and can cut complex layouts. Online cut optimizer takes these restrictions in account during the optimization. CutMaster 2D is a professional rectangular nesting software package. It enables you to maximize the use of material by generating optimized cutting layouts, using advanced algorithms.It is specially adapted for efficient use in sheet metal, furniture, glass and similar industries.

FastCUT® provides a means of nesting a set of rectangular shaped parts into a set of rectangular shaped sheets of stock material. The `grain' of any part may be preserved, preventing rotation of the part during nesting.

FastCUT® assumes use of a shear or guillotine for cutting the parts. The essential feature of such a machine is that it does not cut re-entrant corners; it cuts completely through a workpiece at every operation, and every offcut is itself a rectangle.

The testconditions are presents as follows,.

The testconditions are presents as follows,.

Machines having such features are common in light metal fabrication, joinery using saws, glass cutting and many other applications. Other machines may be simulated, however, the nesting technique is unchanged. Shears with programmable backstops can also be linked to FastCUT®.

Affects your bottom line in such an easy, instant and dramatic way!

There's not a lot of software in this price range that affects your bottom line in such an easy, instant and dramatic way. FastCUT® lets even small job shops incorporate powerful nesting efficiencies into their business whether they use manual or automatic cutting. It gives the operator the complete graphics of the cutting required on a particular job. And as the program allows for dates of jobs and materials used, it can also be used as a very simple and basic quoting system.

While shearing will still be a manual operation, the FastCUT® program will take the tedium out of nesting the patterns, and maximize the use of the material. The program begins with entering the list of required widths and lengths. It will then process the part variations within sheets. It can, in fact, test a whole range of processes over a different range of sheets and the operator can see the sheet layout on the screen. Nesting can be terminated after a specified time has elapsed, or after attaining a specified scrap factor (scrap mass expressed as a percentage of total mass of parts). Nesting can also be interrupted at any time for review of results to date. The program will break down the amount of material into that being used, that which needs to be returned to stock, and that which is scrap. Stock consumption can be prioritized by nominating some items as pre-existing remnant, which forces the use of non-remnant stock where possible. Remnant can be defined by mass and/or width and/or length. Alternatively, all offcut can be defined as scrap.

Works with Coil as well as Sheet and Bar! FastCUT® also provides a means of nesting a set of rectangular shaped parts or bars into a set of coils, rectangular shaped sheets or bars of stock material. Choices for stockfeed are: 1. Lengths as given, 2. Coil cut to mixed lengths, 3. Coil cut to same lengths.

Summary of Features:

- 1D & 2D nesting - Rectangular, Linear & Cut to Length.

- Optimizes Remnant before using Standard size Stocks.

- Job costing calculator produces material cost and return to stock.

- Cutting list/plan calculator for factory staff.

- Produces simple reports for analysis.

- Simple job and quote tracking data.

- DXF Output.

- Kerf Width Allowance: For a shear, guillotine, cropper etc. there is normally no material lost in a cut, although an exception could be made if it were necessary to dress sheared edges as a secondary process. Other thermal or mechanical cutting processes usually result in a finite loss of material which can be specified as Kerf Width Allowance.

- Inch and Metric

- Multi language support (English, Spanish; Chinese [simplified and traditional]; Dutch; Hungarian; Italian; Russian; Thai)

- Add FastCUT® Labels and you can print sticky labels with the cut list data for part identification.

- FastCUT® operates on a single user Windows PC.

- A multi user network version is available for corporates who wish to deploy FastCUT® in a hosted environment such as Citrix or Terminal Services.

- Customized Editions for Metal, Wood and (Flat) Glass are available.

Cutting Optimization Pro 5.9.9 Crack Download Free

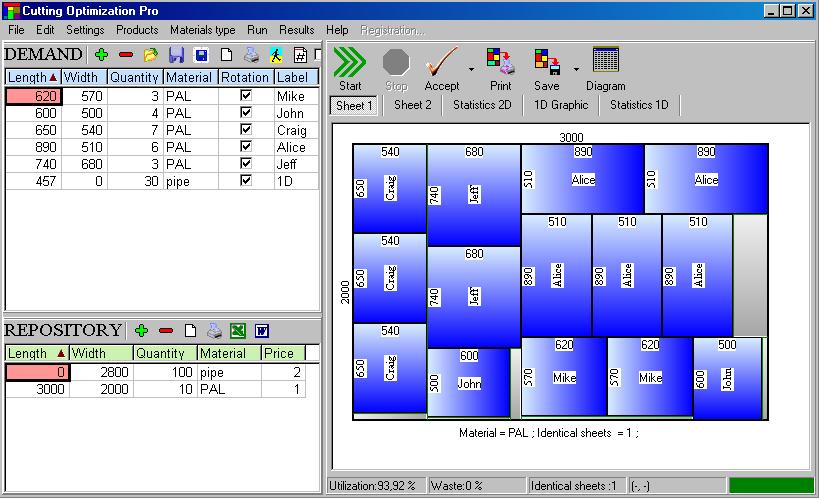

If you are finding an excellent software which proves very powerful for obtaining optimal cutting layouts for rectangular (2D) and linear (1D) pieces then Cutting Optimization Pro 5.9 Crack For window is the one and only solution. Cutting Optimization Pro Crack examines the input parameters and uses its optimization engines (Optimal Programs Cut 2D X and Cut 1D X components) to producing the cutting pattern (in graphical and text mode), which can be printed or saved to your computer system.

Cutting Optimization Pro 5.9 Serial Key is very trusted software for the optimal cutting layouts. Cutting Optimization Pro 5 With Keygen is amazing software that enables the layout of plans when one has different types of material that one needs to cut. The automatic tool computes the dimensions of the pieces whether wood, glass or metal and will design an optimal cutting pattern according to the external size, working in both 1D and 2D optimization.

Cutting Optimization Pro 5.9 License Key is full of various tools which are the best assistance according to all aspects. The Activation key for the Cutting Optimization Pro can automatically compute the size of the pieces needed for building that product.

Cutting Optimization Pro Crack Features:

- Printing the REPOSITORY and the DEMAND of the customer – you may print the pieces that you want to optimize.

- n-guillotine (nested) optimization – The cutting machine can follow the shape of the material. In this case you need to have a complex machine based on laser or flame blade.

- Generates optimal cutting patterns.

- Reduces panel waste and costs – By using the latest achievements in the field of Artificial Intelligence you may obtain reduce the waste by 15%.

- Any size less than 2 billion units- the size of the pieces is limited by the size of the data types introduced by the C++ language.

- Any measurement metric- The way in which you introduce the data is a general one. You don’t have to specify a metric. Just choose a metric in your mind and enter all data using that metric only.

- Adjustable cutting blade thickness- For glass cutting with diamond the cutting blade width is 0, but for wood, metal handling you need a saw blade with a greater width.

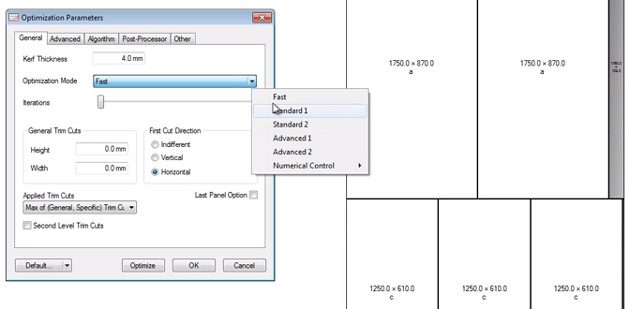

- Adjustable optimization level- One may specify how many layouts to be generated before the solution is outputted. If you don’t have too much time and you don’t have a good computer you may set the Optimization Level to a low level. This feature helps you to run your program on any kind of computer (from 486 to the best processors available today)

- Printing the obtained layouts – on any printer.

- Grain direction control – useful for wood cutting optimisation.

- Automatic offcuts handling – the useful waste is automatically added to the Repository of materials.

- Graphical display black-white and text mode of the obtained results.

- Any number of pieces in the REPOSITORY and DEMAND – virtually no limit for the number of pieces that you want to optimize.

- Printing multiple layouts on the same page – You may print 1, 2, 4 or 6 layouts on the same sheet of paper.

- The cuttings are shown in text format in order to use them with a CNC machine.

- Vertical printing of the labels and edge bands – this will optimise and simplify your layout.

- Edge banding handling – the quantity and the type of material attached to the edges of the wood sheets is manipulated by the program.

Olympus om 1. SYSTEM REQUIREMENTS: Cutting Optimization Pro 5 windows Crack

- 90 MHz

- 8 MB RAM

- 10 MB HDD

How to Crack Cutting Optimization Pro 5.9.9.8 windows?

- Download Trial Version

- Download Cutting Optimization Pro 5.9.9.8 Crack from the Given Links At download-mac-apps.net

- Install And Run The Application

- Click On register

- Registration has done Enjoy all Time Free software Cracks

Recent Posts

- Contoh Dialog For Example

- Total Club Manager 2005 Pci

- Danby Portable Air Conditioner 14000 Btu Installation

- Tc Helicon Voicelive 2 Manual Pdf

- Crack Excel Password Vba Code Help Forum

- Hp 250 G4 Drivers Windows 7 32bit Download

- Virtual Breadboard Full Cracked Windows 7

- Download Lighthouse Family Ocean Drive

- Vitascene Serial Number

- Download Do Filme O Imbativel 2 Dublado Avi

- Bus Simulator 2012 Full Crack Indir

- Dvr 2004 Software